MDF Laser Cutting

MDF laser cutting advantages include :

1 – Accuracy

2 – Internal corners are sharp (not rounded as CNC)

3 – Efficient use of the material

4 – Intricate designs are achievable as MDF cuts very evenly.

Shown here are the cut edges of standard MDF laser cutting, showing how the laser burns the edge black.

From top to bottom : 3mm, 6mm, 9mm, 12mm and 18mm.

You can see how even and sharp the cut is

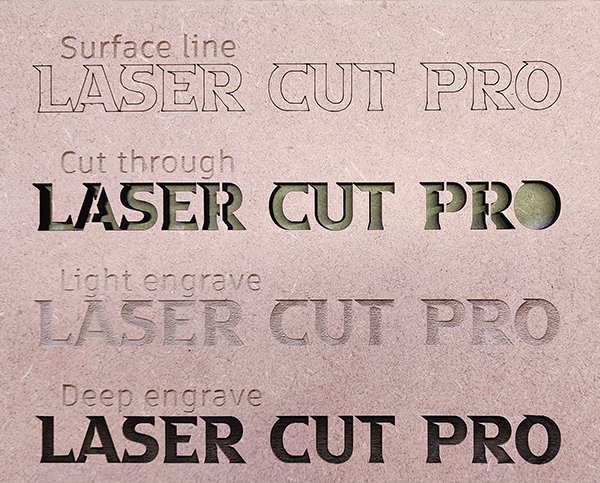

MDF is well-suited for engraving. Displayed here is a sample board with surface lines, sections cut through, and areas that have been engraved.

The surface may be finished and then engraved, or it can be paint-filled after engraving; both methods necessitate masking.

Standard/MR MDF

Our supply: Stock / special order material

Thickness: Available in 2mm, 3mm, 6mm, 9mm, 12mm, 15mm, 18mm

Sheet sizes: Anything up to 2440×1220mm

Self supply: You can also supply your own MDF up to 18mm in thickness and max sheet size

Material Properties

An FSC-certified wood board with a smooth surface, made from softwood fibres blended with wax and resin, offers consistent density and heat tolerance, making it ideal for laser cutting applications. MDF is produced using natural softwood fibres, and it’s important to note that the tone and density may differ between sheets.

MDF Laser Cutting

Dried compressed air is used to keep flaming, scorching and charring to a minimum. This gives a near clean surface result but you will sometimes get slight markings particularly when the laser first pierces the material at the start of the cut line. These easily be removed by sanding with a fine grit sand paper.

By default we DON’T use any protective tape on either side of the MDF board. Heat from the laser causes residues on the laser bed to reflect back onto the material underside, which again can be easily sanded off.

If you would like to use protective tape to prevent burn marks on either side of the material you’ll need to specify this in your job request.

MDF laser cuts with brown / black edge (charring from the burn) which is darker the thicker the MDF being cut. The edge can get dirty and in some cases mark if in contact with another material surface.